Search This Blog

Most Popular

Categories

- Building Construction (87)

- Building Materials (88)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (6)

- Concrete Mix Design (15)

- Concrete Repair (14)

- Concrete Slab (11)

- Construction Equipment (17)

- Construction News (7)

- Design of Structures (20)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (34)

- Material Testing (11)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (13)

- Structural Design (24)

- Structures (17)

- Transportation Engineering (9)

How to Repair Concrete Cracks by Caulking?

Team Prodyogi

March 15, 2023

Cracks and gaps on concrete surfaces are more severe than just an eyesore. If you have cracks in your concrete patio, sidewalks, or driveway; concrete caulking can save you. Concrete caulking is filling concrete cracks or joints using a polymer material called caulk to prevent further expansion of damage.

Caulking for concrete is an essential preventive measure to save the concrete structure from structural damage and instability. It is mostly performed on cracks and expansion joints. The most commonly used caulk for concrete is polyurethane caulk and silicone-based caulk.

In this article, we will discuss the applications of concrete caulking and how to perform the caulking of concrete.

Concrete caulking helps to prevent the primary concern of water seepage thereby blocking all expected issues to the concerned structure.

Silicon caulk possesses high elasticity that imparts the property to adhere well with other materials without cracking or breaking the adjacent material. It expands or contracts with the environmental conditions. It is prized for its elasticity and adhesive property.

Note: The cost of caulk varies with the brand, quantity, location, and higher-end specialized formulations in the caulk.

|

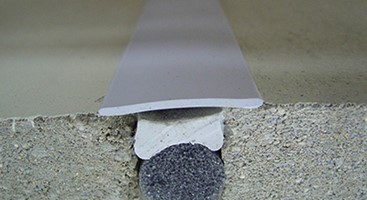

| Image Credits: Tremco |

Caulking for concrete is an essential preventive measure to save the concrete structure from structural damage and instability. It is mostly performed on cracks and expansion joints. The most commonly used caulk for concrete is polyurethane caulk and silicone-based caulk.

In this article, we will discuss the applications of concrete caulking and how to perform the caulking of concrete.

Importance of Concrete Caulking

Concrete caulking is important to prevent the following occurring factors:1. Water Seepage and Erosion

Concrete cracks or joints left unidentified invite moisture and water seepage. The water entering the gaps erodes the base and leads to the settlement of the structure. Besides this, the erosion of the subgrade creates weak points underneath the structure leading to the risk of further cracking.Concrete caulking helps to prevent the primary concern of water seepage thereby blocking all expected issues to the concerned structure.

2. Freeze and Thawing Cycles

The water may enter the pores through the gaps. The water within the pore is prone to freezing and thawing with climatic changes leading to small pores popping. These later form small cracks and propagate to form large cracks.Caulking of these minor cracks or joints in concrete surfaces prevents crack expansion and moisture penetration issues that otherwise lead to structural instability.

3. Weeds and Plants

Sealing up the cracks with caulk keeps plants and weed growth away. This prevents the plant roots to penetrate into the concrete structure and also maintains the looks of the concrete structure. Caulking for concrete is usually performed as a part of concrete maintenance (cleaning and sealing). It assures to stay functional as required and visually appealing for a longer period.Types of Concrete Caulks

Concrete caulks are chosen based on their adhesive and durability properties. The common types of concrete caulk used are:1. Urethane / Polyurethane Caulk

Polyurethane caulks are organic and provide an impermeable adhesive layer for cracks. It prevents moisture, air, and debris from entering the gap filled. It is water resistant, making it suitable for damp environments. It can be painted with any color to match the surface. Hence, it is a good choice for a patio, porch, or other spaces with unique colors.One of the major downsides of urethane caulk is that it has a lifetime of a few years as it degrades over time.

2. Silicon Caulk

Silicon caulk is inorganic and specialized in filling the gaps between concrete and another adjacent surface made of brick, wood, or metal. It is flexible, sturdy, and not degradable compared to urethane caulks.Silicon caulk possesses high elasticity that imparts the property to adhere well with other materials without cracking or breaking the adjacent material. It expands or contracts with the environmental conditions. It is prized for its elasticity and adhesive property.

Note: The cost of caulk varies with the brand, quantity, location, and higher-end specialized formulations in the caulk.

How to Caulk a Concrete Crack or Joints?

Materials Required

- Polyurethane Caulk/Silicon Caulk

- Mineral spirits

- Foam Backer rod

- Caulk Gun

Preparations

- Choose a sunny day to perform caulking

- Clean up the area that needs caulking.

- Clean the cracks from dirt, debris, and dust.

Work Procedure

Step 1: Evaluate the size of the crack or joint

If the depth of the crack or the joint is very deep, you do not have to fill the complete crack until the bottom depth with caulk. Instead, we make use of a foam backer (a flexible strip of foam) to fill the half depth and followed by the caulk. A foam backer is used if the crack is larger than 1/2 inch wide and 1 inch deep.

Step 2:Install the Foam Backer Rod

If the crack or joint is large, use a foam backer rod into the gap with your fingers. The rod is set inside the crack lower than the surface of the concrete.

Step 3: Apply the Caulk

Cut the tip of the caulk tube and load it into the caulking gun. Start squeezing a bead of caulk into the crack or joint smoothly. Smooth the caulk and spread it using a tool or with the back of a small spoon. It is leveled below the concrete surface to prevent its exposure to wear and tear.

Follow the instructions given in the caulk tube to find out the drying and curing period. If it is not painted, it is finished with dry sand.

Find Your Tools:

Things to Remember

- If the caulk shrinks, reapply it to form a smooth layered bead immediately.

- An automatic-release caulking gun is much easier to work compared to a manual caulking gun.

- Place the caulking gun to the bottom of the opening while applying it to avoid bubbles.

Read More On: How to Fix a Hole in Concrete Floor?

Most Visited

Soil Sampling Methods| Undisturbed and Disturbed Samples

November 08, 2023

Boring Methods for Soil Exploration

November 02, 2023

Steel Column Connected to Concrete Masonry Wall

October 11, 2017

How to Choose Good Quality Aggregates for Construction?

August 10, 2021

What are Infiltration Wells?

April 15, 2024

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Structure of Timber |Macrostructure and Microstructure

March 22, 2024

Search This Blog

MUST READ

What is PERT? Objectives, Pros & Cons

September 10, 2017

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Contact Form

Footer Menu Widget

Created By SoraTemplates | Distributed By Gooyaabi Templates

0 Comments

Commenting Spam Links Are Against Policies