Search This Blog

Most Popular

Soil Sampling Methods| Undisturbed and Disturbed Samples

November 08, 2023

What is Development Length (Ld) in Construction?

August 14, 2025

Categories

- Building Construction (91)

- Building Materials (89)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (6)

- Concrete Mix Design (15)

- Concrete Repair (14)

- Concrete Slab (11)

- Construction Equipment (17)

- Construction News (7)

- Design of Structures (21)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (35)

- Material Testing (11)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (13)

- Structural Design (24)

- Structures (18)

- Transportation Engineering (9)

Soil Sampling Methods| Undisturbed and Disturbed Samples

Team Prodyogi

November 08, 2023

Soil sampling is the process of obtaining samples of soil from the desired depth at the desired location in a natural deposit to assess its engineering properties for the design of the foundation. The device that is used to collect soil samples is called a sampler. Boring and sampling methods in soil exploration go hand in hand during soil investigation.

Soil samples can be broadly classified into undisturbed samples and disturbed samples. These are collected by various boring methods and unique samplers.

In this article, we will discuss in detail undisturbed and disturbed soil samples along with various soil sampling methods.

Undisturbed and Disturbed Soil Samples

Samples of soils taken from natural deposits can be:

- Undisturbed samples

- Disturbed samples

Undisturbed Samples

Undisturbed samples are those samples whose natural structure is preserved and it is subjected to minimum disturbances. It has minimal disturbance to its structure, texture, density, natural water content, and stress condition. These samples are suitable for strength tests and consolidation tests.

The tube samples and chunk samples are examples of undisturbed samples. These samples are collected using a specialized sampler.

Collecting a perfectly undisturbed sample is difficult and the samples may contain some undisturbed soil at the top and the bottom of the sample length.

Disturbed Soil Samples

Disturbed soil samples are soil samples whose natural structure is modified partly or fully during the sampling process. The tests of structural properties of a disturbed soil sample will not be representative of in-situ conditions, and only the properties of the soil grains. These can be classified into:

- representative samples

- non-representative samples

Representative samples are those that contain all the mineral constituents of the soil, but the structure of the soil may be significantly disturbed. These samples are suitable for the identification and determination of certain physical properties of soil like grain specific gravity and Atterberg Limits.

Non-representative samples are soil samples that consist of a mixture of materials from various soil or rock strata or are samples from which some mineral constituents have been lost or mixed up. Soil samples obtained from auger boring and wash borings are of this type.

Factors Affecting Soil Disturbance

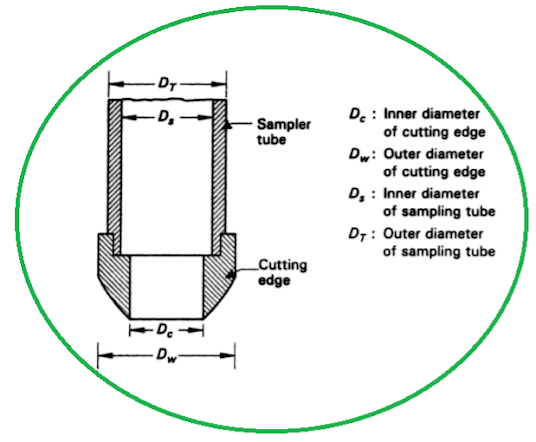

The design features of the above-mentioned samplers influence the "degree of disturbance" of the soil sample collected. This includes the dimensions of the cutting edge and those of the sampling tube. Consider a sampling tube with a cutting edge with the following diameter dimensions Dc, Dw, Ds, and Dt as shown in the figure below.

The area ratio mentioned above is the most critical factor that affects the sample disturbance. Area ratio is given by the ratio of the displaced volume of the soil to that of the soil sample collected. If Ar is less than 10%, the sample disturbance is considered small. If Ar is larger than 30% for thick-wall samplers like split-spoon and may be as low as 6 to 9 % for thin-wall samplers like Shelby tubes.

In the case of rock samples, we consider the Recovery ratio Rr. This is given as the ratio of the Length of the sample within the tube and the depth of penetration of the sampling tube.

Rr = L/H;

For a satisfactory rock sample should have an Rr value of 96% to 98%.

Soil Sampling Methods

Sampling methods are employed to collect soil and rock samples from the boreholes created by the boring methods. They can be classified based on two categories:A. Based on Area Ratio

- Thin-Walled Tube Sampler or Shelby Tube Sampler

- Thick-walled sampler or Split-Spoon Sampler

B. Based on Mode of Operation

- Open Drive Sampler

- Piston Sampler

- Rock Core Sampling

1. Thin-Walled Tube Sampler

A thin-walled tube sampler or Shelby tube sampler is primarily used for collecting undisturbed soil samples in soft to medium-stiff cohesive soils. It is an open-tube sampler with a lower area ratio (Ar = 10%) hence giving less disturbed soil samples.

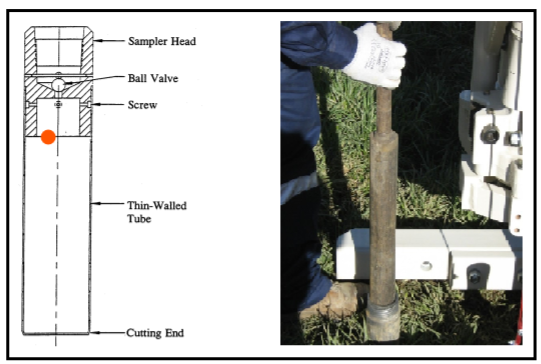

|

| Fig. Thin-Wall Tube or Shelby Tube Samplers |

Thin-wall tube sampler consists of a thin-wall metal tube connected to a sampler head as shown above. The sample head contains a ball check valve and ports to permit the escape of water or air from the sample tube when the soil sample enters it.

|

| Fig. Thin-Walled Tube Sampling Process |

The slender tube has a narrow inner diameter and outside diameters that vary and are made from materials like carbon steel, galvanized steel, stainless steel, or brass, depending on the specific conditions.

To use it, the sampler is pushed into the ground using hydraulic pressure, with the option to rotate it in some cases. The tube should only be inserted up to a certain depth, leaving room for any loose material at the bottom of the borehole. After collection, the soil sample is allowed to swell within the tube, cut, and then brought to the surface. Some soil at the bottom is removed for analysis.

To preserve the sample, the ends of the tube are sealed with wax or O-ring packers, and plastic caps are placed over them. The sample is stored upright and protected from freezing or drying out. It's important to label the tube with relevant project and sample information.

Field extrusion of samples is discouraged due to potential issues, and it's generally better to transport the entire tube to a laboratory for proper handling and extrusion following established procedures. Proper labeling ensures that samples don't get mixed up during storage and analysis.

Standard Reference: Thin-Walled Tube Sampling [ASTM D1587-08: “Standard Practice for Thin-Walled Tube Sampling of Soils for Geotechnical Purposes”].

2. Thick-walled sampler or Split-Spoon Sampler

A split-spoon sampler or thick-wall sampler consists of a long, slender hollow tube with a split or open section near its lower end to collect soil samples. The tube splits into two equal halves lengthwise. During the sampling process, they are locked and it is unlocked while retrieving the samples. It is the most common method used for standard penetration tests (SPT) on soil.

|

| Fig. Split-Spoon Sampler |

The area ratio of these samplers is greater than 30 percent leaving disturbed samples for the test procedure.

3. Open Drive Sampler

Open drive sampler consists of a tube open at its lower end that is manually or mechanically driven or hammered into the ground thus collecting samples without significantly disturbing the natural soil environment. Hence, it is used to collect undisturbed soil samples. Thin-walled and thick-walled tube samplers are a few types of open-drive

samplers.

samplers.

4. Piston Sampler

A piston sampler is basically a thin-wall tube sampler with a piston, road, and a modified sampler head. It is used to collect undisturbed soil samples from soft soil where the sample recovery is often difficult and sometimes in stiff soils.

A piston sampler is also called as Osterberg Piston sampler whose working is given below.

The sampler is equipped with a piston positioned at the base of the sampling tube. It's gently lowered into the borehole and, once at the bottom, the piston rod is secured relative to the ground surface. Hydraulic or mechanical pressure is then used to slowly push the thin-wall tube into the soil; no forceful driving is involved.

After sampling, the sampler is taken out of the borehole, the vacuum between the piston and the sample is released, and jar samples are collected from the top and bottom of the sample for identification.

This method yields high-quality samples with a high probability of success. The fixed piston prevents excessive soil entry at the start of sampling, ensuring recovery ratios don't exceed 100 percent. It also maintains a consistent soil entry rate throughout the push, increasing the chance of 100 percent recovery.

This method yields high-quality samples with a high probability of success. The fixed piston prevents excessive soil entry at the start of sampling, ensuring recovery ratios don't exceed 100 percent. It also maintains a consistent soil entry rate throughout the push, increasing the chance of 100 percent recovery.

Additionally, the sampler's head maintains a better vacuum than the ball valve in thin-walled tube (Shelby) samplers, resulting in superior sample retention.

5. Rotary Sampler

Rotary sampler involves rock coring in which the sampler consists of a tube or core barrel with a cutting bit at its lower end that cuts an annular hole in a rock mass and creates a cylinder or core of rock which is recovered in the core barrel.

Here, the outer tube has the cutting teeth and the inner thin wall is removable. These rock cores are normally obtained by rotary drilling.

|

| Fig. Rock Coring Sampling Process Image Credits: www.uky.edu |

Also called rock core sampling, the procedure provides an undisturbed rock sample. It is not only suitable for rocks, but also for hard cohesive soils.

Conclusion

Soil samples collected require special care while being taken from the site to the laboratory for tests. The disturbances on the soil sample due to careful handling would result in high variations in results. Hence, it is essential to have experienced personnel in this regard to conduct the sampling process without compromising quality.

Most Visited

Soil Sampling Methods| Undisturbed and Disturbed Samples

November 08, 2023

What is Development Length (Ld) in Construction?

August 14, 2025

Steel Column Connected to Concrete Masonry Wall

October 11, 2017

Structure of Timber |Macrostructure and Microstructure

March 22, 2024

Boring Methods for Soil Exploration

November 02, 2023

How to Choose Good Quality Aggregates for Construction?

August 10, 2021

What are Infiltration Wells?

April 15, 2024

Search This Blog

MUST READ

What is PERT? Objectives, Pros & Cons

September 10, 2017

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Contact Form

Footer Menu Widget

Created By SoraTemplates | Distributed By Gooyaabi Templates

0 Comments

Commenting Spam Links Are Against Policies