Search This Blog

Most Popular

Soil Sampling Methods| Undisturbed and Disturbed Samples

November 08, 2023

What is Development Length (Ld) in Construction?

August 14, 2025

Categories

- Building Construction (91)

- Building Materials (89)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (6)

- Concrete Mix Design (15)

- Concrete Repair (14)

- Concrete Slab (11)

- Construction Equipment (17)

- Construction News (7)

- Design of Structures (21)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (35)

- Material Testing (11)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (13)

- Structural Design (24)

- Structures (18)

- Transportation Engineering (9)

Soak Pit - Function, Types & Design

Team Prodyogi

September 15, 2023

A soak pit is a type of effluent disposal system used to treat and dispose of the effluent coming out of a pre-treatment system, safely to the ground. It is a type of soil absorption system - a smaller version of leach fields and is suitable for treating and disposing of small effluent discharges wherever a wastewater treatment unit or system does not exist.

Watch Video: What is a Soak Pit?

Let's discuss in this article the functions of soak pits, their types, and their design features.

The term "leaching area" refers to the portion of land or soil surface where effluent (liquid waste or wastewater) is distributed or discharged for the purpose of natural filtration, treatment, and absorption. The primary function of a leaching area is to allow the effluent to percolate or seep into the soil gradually, where it undergoes treatment through physical, chemical, and biological processes. These processes help remove impurities, pathogens, and pollutants from the effluent before it reaches groundwater or the environment.

When wastewater from sources like septic tanks or greywater systems is directed into a hollow soak pit, it percolates directly into the surrounding soil. The soil's natural filtration properties help to treat the wastewater by removing impurities and pathogens as it moves through the soil layers. The primary treatment mechanism in a hollow soak pit is biological filtration.

Wastewater flows into the filled soak pit, where it encounters the filling material. The filling material provides additional surface area for the wastewater to interact with and facilitates better distribution of the effluent. As the wastewater moves through the layers of filling material, it is treated through physical and biological processes. The gravel or stones act as a filter and provide space for beneficial microorganisms to break down organic matter. Treated effluent then percolates into the surrounding soil.

The choice between a hollow and filled soak pit depends on factors such as soil type, site conditions, and the specific wastewater management requirements. It's important to consult with a local expert or follow local regulations to determine the most suitable option for your situation and ensure proper installation and maintenance.

Calculating the leaching area for a soil absorption system like a soak pit or dispersion trench involves determining the total area of the system that will be in contact with the soil to allow for the percolation of effluent. To calculate the leaching area, follow these steps:

Step 1: Determine the Maximum Rate of Effluent Application (Q)

Before calculating the leaching area, you'll need to determine the maximum rate at which effluent can be applied to the soil, which is denoted as Q (measured in liters per day per square meter or lpd/m^2). You can use the formula:

Step 2: Calculate the Total Daily Effluent Volume (V)

Next, calculate the total daily effluent volume that needs to be treated. This is typically based on the amount of wastewater generated by your source (e.g., a household, a septic tank). It's measured in liters per day (lpd).

Step 3: Calculate the Required Leaching Area (A)

To find the leaching area required to accommodate the effluent, use the formula:

A soak pit also called a leach pit or seepage pit is a covered porous walled chamber that allows effluent water to slowly soak through different filter layers and reach the ground.

Let's discuss in this article the functions of soak pits, their types, and their design features.

Table of Contents

- Working of Soak Pit

- Types of Soak Pits

- Design of Soak Pits

- Calculations

- Suitability of Soak Pits

- Advantages & Disadvantages

Working of Soak Pit

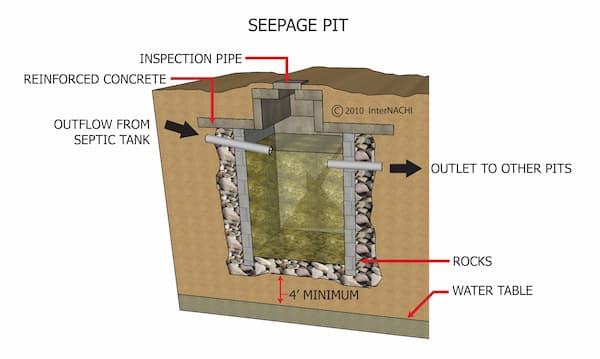

A soak pit chamber receives the effluent coming out from a primary treatment plant like a septic tank, aerobic treatment system, etc. Hence it partially treats a pre-settled effluent.

A soak pit consists of different layers of filters made of soil, gravel, or other mediums enclosed within a small chamber. The wastewater (greywater and blackwater) after their pretreatment, slowly percolates through this chamber. During the movement, the organic matter is digested by the micro-organisms and the remaining water reaches the bottom and gets absorbed within the soil.

The sub-soil layers in this arrangement should be permeable enough to allow faster saturation thus avoiding clogging. As it is a small chamber, soak pits are only used in areas where there is no high discharge of effluents.

Types of Soak Pits

The three major types of soak pits are:

- Hollow soak pits

- Filled soak pits

1. Hollow Soak Pit

A hollow soak pit is essentially a pit dug into the ground without any internal filling material such as gravel or stones. It is typically a large, empty cavity in the ground. |

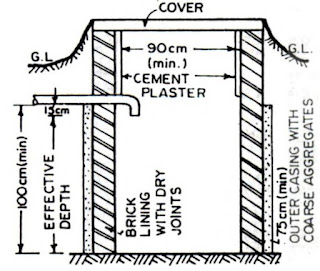

| Hollow and Lined Soak Pit |

When wastewater from sources like septic tanks or greywater systems is directed into a hollow soak pit, it percolates directly into the surrounding soil. The soil's natural filtration properties help to treat the wastewater by removing impurities and pathogens as it moves through the soil layers. The primary treatment mechanism in a hollow soak pit is biological filtration.

Advantages

- Simplicity: Hollow soak pits are straightforward to construct and require minimal materials.

- Cost-effective: They are often more budget-friendly compared to filled soak pits.

- Suitable for certain soil types: They can work well in soils with good natural drainage properties.

Considerations

- Soil Conditions: The effectiveness of a hollow soak pit depends on the soil's ability to filter and treat wastewater. It may not be suitable for soils with poor drainage or high groundwater levels.

- Sizing: Proper sizing is crucial to ensure that the soil has enough capacity to treat the wastewater effectively.

2. Filled Soak Pit

A filled soak pit, also known as a leach field or absorption trench, includes layers of filling materials such as gravel, stones, or coarse sand within the excavation. |

| Filled and Unlined Soak Pit |

Wastewater flows into the filled soak pit, where it encounters the filling material. The filling material provides additional surface area for the wastewater to interact with and facilitates better distribution of the effluent. As the wastewater moves through the layers of filling material, it is treated through physical and biological processes. The gravel or stones act as a filter and provide space for beneficial microorganisms to break down organic matter. Treated effluent then percolates into the surrounding soil.

Advantages

Enhanced Treatment: Filled soak pits typically offer better treatment capabilities than hollow soak pits due to the additional surface area and microbial activity in the filling material.

Suitable for various soil types: Filled soak pits can work in a wider range of soil conditions.

Suitable for various soil types: Filled soak pits can work in a wider range of soil conditions.

Considerations

- Proper Design: The design of the filling material and the dimensions of the pit must meet local regulations and standards.

- Maintenance: Regular maintenance, including clearing any accumulated sludge or debris in the filling material, is essential to ensure the long-term effectiveness of a filled soak pit.

The choice between a hollow and filled soak pit depends on factors such as soil type, site conditions, and the specific wastewater management requirements. It's important to consult with a local expert or follow local regulations to determine the most suitable option for your situation and ensure proper installation and maintenance.

Design of a Soak Pit

When designing a soil absorption system like a soak pit it is necessary to consider the percolation rate of the soil so that we can estimate the maximum rate of effluent discharge. This helps to calculate the total subsurface soil area required for the soak pits or dispersion trenches.

If Q is the maximum rate of effluent application in lpd/metre square of leaching surface and 't' is the standard percolation rate for the soil in minutes per cm, then;

Q = 130/√t

Soak pits can be circular or rectangular in shape. Circular pits are less likely to collapse because the pressure from the surrounding soil is evenly distributed compared to rectangular pits. The following are design considerations followed while constructing a soak pit.

- A soak pit is constructed at a safe distance (30 m) from a drinking water source.

- A soak pit is constructed as a simple pit at a depth of 1.5 m to 4 m. Generally, the unit constitutes a volume of 1-metre cube.

- The internal diameter must not be less than 90 cm.

- As a simple thumb rule, it must not be less than 2m above the groundwater table.

- If you are constructing a pit deeper than 1.2 meters it is advised to provide temporary support by lining or shoring to prevent collapse.

Calculations

Step 1: Determine the Maximum Rate of Effluent Application (Q)

Before calculating the leaching area, you'll need to determine the maximum rate at which effluent can be applied to the soil, which is denoted as Q (measured in liters per day per square meter or lpd/m^2). You can use the formula:

Q = 130 / √t

Step 2: Calculate the Total Daily Effluent Volume (V)

Next, calculate the total daily effluent volume that needs to be treated. This is typically based on the amount of wastewater generated by your source (e.g., a household, a septic tank). It's measured in liters per day (lpd).

Step 3: Calculate the Required Leaching Area (A)

To find the leaching area required to accommodate the effluent, use the formula:

A = V / Q

'A' represents the required leaching area in square meters (m^2).

'V' is the total daily effluent volume in liters per day (lpd).

'Q' is the maximum rate of effluent application in lpd/m^2 (calculated in Step 1).

Step 4: Account for Design Considerations

Keep in mind that the calculated leaching area is a minimum requirement. In practice, you may need to increase the leaching area to account for design considerations and to ensure the system functions effectively. Factors that could necessitate an increase in leaching area include:Local regulations and standards.

Step 5: Design the Leaching Area

With the required leaching area determined, you can proceed to design the soak pit or dispersion trench system accordingly. Pay attention to layout, depth, and any additional features that may be necessary for proper effluent distribution and treatment.

It's important to note that soil absorption systems should be designed and installed in compliance with local regulations and guidelines. Additionally, conducting percolation tests to determine the actual percolation rate of the soil at your site is crucial for accurate sizing and design. Consulting with a qualified engineer or environmental specialist experienced in wastewater treatment can help ensure that your system is designed correctly for your specific conditions.

'V' is the total daily effluent volume in liters per day (lpd).

'Q' is the maximum rate of effluent application in lpd/m^2 (calculated in Step 1).

Step 4: Account for Design Considerations

Keep in mind that the calculated leaching area is a minimum requirement. In practice, you may need to increase the leaching area to account for design considerations and to ensure the system functions effectively. Factors that could necessitate an increase in leaching area include:Local regulations and standards.

- Soil characteristics, including variability in percolation rates across the area.

- Seasonal variations in soil moisture and groundwater levels.

- Specific design parameters, such as the depth and configuration of the absorption system.

Step 5: Design the Leaching Area

With the required leaching area determined, you can proceed to design the soak pit or dispersion trench system accordingly. Pay attention to layout, depth, and any additional features that may be necessary for proper effluent distribution and treatment.

It's important to note that soil absorption systems should be designed and installed in compliance with local regulations and guidelines. Additionally, conducting percolation tests to determine the actual percolation rate of the soil at your site is crucial for accurate sizing and design. Consulting with a qualified engineer or environmental specialist experienced in wastewater treatment can help ensure that your system is designed correctly for your specific conditions.

Suitability of Soak Pits

Let's discuss the suitability of soak pit construction:

- Soak pits are suitable where the effluent discharge from the pre-treatment is not too high. This can save clogging and related hygiene issues.

- Soak pits must be constructed in areas with high saturation capacity and permeability. In general, they are most suitable for sandy soils with good absorption properties. It does not work for clayey soils, hard-packed, or rocky soils.

- It is preferred in locations where the water table is low.

Advantages of Soak Pits

- Cost-effective wastewater disposal.

- Simple design suitable for various locations.

- Effective treatment through natural processes.

- Reduced environmental impact, protecting groundwater.

- Space-efficient for densely populated areas.

- Low energy consumption.

- Versatile, handling different wastewater types.

Disadvantages of Soak Pits

- Complex sizing based on soil and wastewater factors.

- Requires regular maintenance to prevent clogging.

- May not fully treat all contaminants or pathogens.

- Unsuitable for high groundwater or impermeable soils.

- Environmental risks without proper design and care.

- Requires compliance with local regulations.

- Possible odor issues if not well-designed or maintained.

Most Visited

Soil Sampling Methods| Undisturbed and Disturbed Samples

November 08, 2023

What is Development Length (Ld) in Construction?

August 14, 2025

Steel Column Connected to Concrete Masonry Wall

October 11, 2017

Structure of Timber |Macrostructure and Microstructure

March 22, 2024

Boring Methods for Soil Exploration

November 02, 2023

How to Choose Good Quality Aggregates for Construction?

August 10, 2021

What are Infiltration Wells?

April 15, 2024

Search This Blog

MUST READ

What is PERT? Objectives, Pros & Cons

September 10, 2017

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Contact Form

Footer Menu Widget

Created By SoraTemplates | Distributed By Gooyaabi Templates

0 Comments

Commenting Spam Links Are Against Policies