Search This Blog

Most Popular

What is Development Length (Ld) in Construction?

August 14, 2025

Categories

- Building Construction (89)

- Building Materials (89)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (6)

- Concrete Mix Design (15)

- Concrete Repair (14)

- Concrete Slab (11)

- Construction Equipment (17)

- Construction News (7)

- Design of Structures (20)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (35)

- Material Testing (11)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (13)

- Structural Design (24)

- Structures (17)

- Transportation Engineering (9)

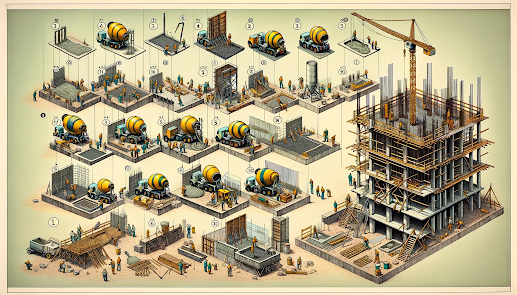

Step-by-Step guide to Concrete Construction in Structures

Team Prodyogi

January 23, 2024

Building with concrete is more than just pouring a mixture and waiting to set. From humble mixtures of crushed stone and water to today's sophisticated industry, concrete has stood the test of time for its safety and durability.

Concrete has evolved since the 19th century, blending modern tech with classic methods for strong structures globally. It starts with estimating materials, prepping the site, creating forms, placing reinforcements, mixing, pouring, and the vital finishing and curing steps.

Concrete isn't just mix-and-match; it's the trusted choice for architects crafting skyscrapers to cozy homes. Strength, durability, and flexibility make it a superstar. Its construction methods vary based on size, materials, and environment. Pre/post-contract activities shape the process – it's a tailored journey.

Whether you're a construction pro or planning your project, these steps are your roadmap. Let’s bite the bullet then!

Placing Reinforcement

Before the concrete takes the spotlight, we need a supporting cast. Reinforcement bars are like the backbone, providing strength and structure to the concrete.

Each ingredient, be it aggregates, cement, or water, needs to be measured with a 3% accuracy of the batch quantity, while admixtures should be within 5% accuracy.

The options for concrete transportation include mortar pans, wheelbarrows, chutes, dumpers, buckets with ropeways, belt conveyors, skips with hoists, and pumping.

Arham Arshad is an expert in steel building design and construction, Northern Steel Buildings & Construction specializes in creating durable, cost-effective solutions for a wide range of industries. With a focus on quality and customer satisfaction, the team leverages cutting-edge technology and innovative practices to deliver exceptional results. Contact Info: Mendon, Utah 84325,(435) 677-7300.

Concrete has evolved since the 19th century, blending modern tech with classic methods for strong structures globally. It starts with estimating materials, prepping the site, creating forms, placing reinforcements, mixing, pouring, and the vital finishing and curing steps.

Concrete isn't just mix-and-match; it's the trusted choice for architects crafting skyscrapers to cozy homes. Strength, durability, and flexibility make it a superstar. Its construction methods vary based on size, materials, and environment. Pre/post-contract activities shape the process – it's a tailored journey.

Whether you're a construction pro or planning your project, these steps are your roadmap. Let’s bite the bullet then!

Pre-concrete Construction Workouts

1. Project Location

First things first – where's the spotlight? Pin down the perfect location for the building. Sometimes, we don't have much choice, but we need to tackle any potential issues, especially with the soil.2. Building Plan

Time to sketch out the blueprint! Architectural engineers create the plan based on the building's needs, like the script for a play.3. Building Design

Now, let's add some structure! Structural engineers design the frame, deciding on the foundation based on soil investigation and the load it will carry.4. Estimate and Budget

Counting the cost! Building estimators tally up materials, and work items, and prepare a sheet with all the construction costs.5. Soil Investigation

Digging into the details! Before the design, a soil investigation report is a must. We need to know the soil's properties, types, and load-bearing capacity.6. Building Permit

Time to get the green light! Approval from the City Development Authority is crucial. It's like getting permission to put on the show, and we need all our documents in order.7. Choose a Builder

Picking the star of the show! Selecting the builder is a big deal. The contract details need to be crystal clear, like setting the terms for a collaboration.8. Preparing for Action

With everything set, it's showtime! The preconstruction activities are like the rehearsals before the big performance.Post-concrete Construction Workouts

1. Site Preparation

Before the concrete dance begins, the ground needs to be prepped. It's like setting the stage for a performance. We excavate, level the ground, and compact it to make sure it's all smooth and ready.2. Building Formwork

Now, we create molds or forms to shape our concrete masterpiece. These forms can be made of various materials like steel or wood. It's like crafting a mold for a sculpture.Placing Reinforcement

Before the concrete takes the spotlight, we need a supporting cast. Reinforcement bars are like the backbone, providing strength and structure to the concrete.

3. Mixing Concrete

Time to mix things up! We blend the ingredients until we get a uniform color and the right consistency. It's like baking, but instead of cookies, we get solid concrete.Each ingredient, be it aggregates, cement, or water, needs to be measured with a 3% accuracy of the batch quantity, while admixtures should be within 5% accuracy.

4. Pouring Concrete

The grand moment! The mixed concrete takes center stage, either pumped or manually transported. Just like a show, we use vibrators to make sure it's a seamless performance. Remember, after mixing, concrete should reach its destination promptly to maintain its uniformity. Using trucks with agitators allows a 2-hour window, while trucks without agitators have a 1-hour limit.The options for concrete transportation include mortar pans, wheelbarrows, chutes, dumpers, buckets with ropeways, belt conveyors, skips with hoists, and pumping.

5. Finishing Concrete

After the concrete show, it's time for the finishing act. Using tools like screeds and trowels, we smooth out the surface. It's like the encore to a great performance. During the mixing process, some air gets trapped, and there might be partial segregation, both affecting concrete quality. Compaction is crucial to eliminate trapped air, prevent segregation, and create a uniform, dense mass.6. Curing of Concrete

Last but not least, we let our concrete creation rest and gain strength. Curing is like pampering freshly laid concrete—it's crucial. There's a magic combo in the concrete world called C3S and C2S, contributing to early strength. This power duo kicks in within three weeks. The later strength boost from C2S takes its sweet time.Conclusion

Building with concrete is no simple task – it's a journey from crushed stone mixes to today's high-tech industry. It's more than just pouring; it's a carefully crafted process. From estimating materials to post-construction, it's a tailored journey. For a strong start, location and planning are key – it's like setting the stage for a show. Following these steps and embracing the latest techniques ensures the creation of robust buildings.Explore More On Concrete Mix Design and Concrete Technology

Author Bio

Arham Arshad is an expert in steel building design and construction, Northern Steel Buildings & Construction specializes in creating durable, cost-effective solutions for a wide range of industries. With a focus on quality and customer satisfaction, the team leverages cutting-edge technology and innovative practices to deliver exceptional results. Contact Info: Mendon, Utah 84325,(435) 677-7300.

Most Visited

Soil Sampling Methods| Undisturbed and Disturbed Samples

November 08, 2023

Boring Methods for Soil Exploration

November 02, 2023

What is Development Length (Ld) in Construction?

August 14, 2025

Steel Column Connected to Concrete Masonry Wall

October 11, 2017

Structure of Timber |Macrostructure and Microstructure

March 22, 2024

How to Choose Good Quality Aggregates for Construction?

August 10, 2021

What are Infiltration Wells?

April 15, 2024

Search This Blog

MUST READ

What is PERT? Objectives, Pros & Cons

September 10, 2017

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Contact Form

Footer Menu Widget

Created By SoraTemplates | Distributed By Gooyaabi Templates

0 Comments

Commenting Spam Links Are Against Policies