Scaffolding is a temporary structure that is used either to support an original structure or to function as a platform for the workers to perform construction works. It is a framework of horizontal, vertical, and inclined members. Every scaffolding constructed must be strong and firm to support the weight of the workers and other construction materials laid on it.

|

| Fig.1. Steel Scaffolding |

Scaffolding is designed for a particular construction work which varies in material, and layout. This is decided based on the type of work.

In this article, let's discuss the various components, types, and features of scaffolding used in construction work.

Features of Scaffolding

- Scaffolding are temporary structure erected close to the main work to provide a working platform for workers and to separate other storage of building materials, tools, and plants away from the main work for better safety and organizing. They are also called staging.

- Scaffolding is used for construction, maintenance, repair, alteration, demolition, painting, etc.

- Any construction work that needs access more than 1.5m in height from the ground level demands scaffolding.

- Scaffolding members can be made out of timber or steel.

Functions of Scaffolding

The main functions of scaffoldings are to:

- Act as a working platform so that the worker can stand on the platform and perform the work safely and easily.

- Act a platform to load materials - so that workers can place materials and tools to conduct their work.

- As a walking platform, so that workers can have a walking path to transport materials and logistics.

Components of Scaffolding

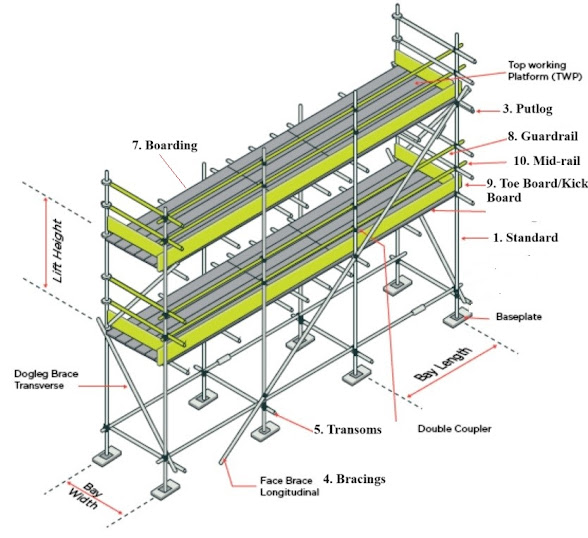

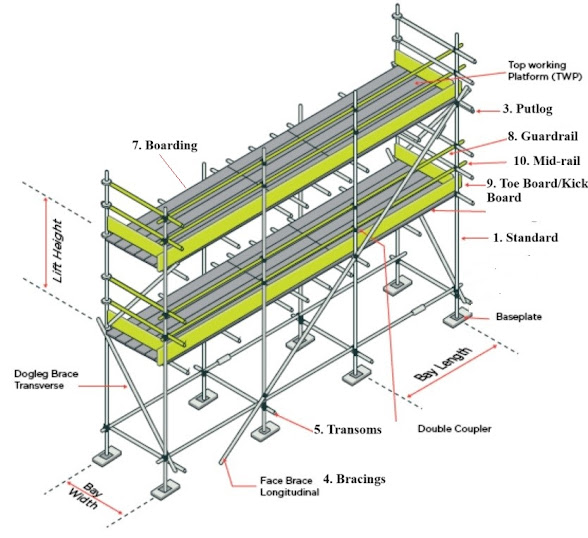

The figure below shows a scaffolding arrangement depicting the important components of the framework. As shown, there are ground-floor and first-floor arrangements. The component - Standard (1) will be facing the main wall of the structure and workmen will stay on the platform boarding (2) during construction [ Figure 2]. The topmost platform in a scaffolding formwork is called as the Top Working Platform (TWP).

Let's familiarise each component of a scaffolding one by one. The major components of a scaffolding are:

|

| Fig.2. Components or Parts of a Scaffolding |

1. Standards: Vertical members of the framework that are supported on the ground or drums or embedded into the ground.

2. Ledgers: Horizontal supporting members that run parallel to the wall or the facing main structure.

3. Braces: Diagonal members end fixed on the standards, to provide lateral support to the whole framework.

4. Putlogs: Putlogs are traverse members supported over the ledgers, with one end fixed on the wall at one end and the other end free, as shown in Figure 2. These members support elements to create a platform to support workmen.

5. Transoms: When both ends of a putlog are supported on ledgers, we call it a transom. In most cases, transom acts as handrails.

6. Bridle: This is a small member used to bridge an opening in the wall so that it can support one end of the putlog (Figure 3).

|

| Fig.3. Bridle for Scaffolding Connection in Wall Openings |

7. Boarding: These are horizontal platforms to support the workmen and material. These boardings are supported on the putlogs. (Figure 2).

8. Guard Rail: These are rails provided at the working level parallel to the ledgers.

9. Toe Board: These are boards that are placed parallel to the ledgers and are supported on putlogs at the level of the working platform.

10. Mid Rails: Mid rails are also guard rails provided at mid between the boarding and the guardrail for extra support and safety as shown in Figure 2.

11. Couplers: Also called couplers are fittings used to join the various components of a scaffold together (Figure 4).

|

| Fig.4. Couplers used in Scaffolding Connection |

12. Scaffold Tie: Scaffold ties are used to secure the scaffold to other structures. Figure 5 shows the scaffolds tied to the wall using rigid ties at the top and bottom.

|

| Fig.5. Scaffold Tie |

Types of Scaffolding

All scaffolding can be classified into two main categories supported scaffoldings and suspended scaffoldings.

Let's discuss each type one by one.

Table 1: Types of Scaffolding

| A. Supported Scaffolding Types | B. Suspended Scaffolding Types |

|---|

| 1. Brick Layer Scaffolding | Catenary Scaffolding |

| 2. Mason's Scaffolding | Float Scaffolding |

| 3. Cantilever Scaffolding | Interior Hung Scaffolding |

| 4. Trestle Scaffolding | Two-Point (Swing Stage) Scaffolding |

| 5. Mast Climber Scaffolding | Multilevel Scaffolding |

| 6. Ladder Jack Scaffolding | Multipoint Adjustable Scaffolding |

| 7 Mobile Scaffolding | Single-point Adjustable Scaffolding |

| 8. Pole/Wood Pole Scaffolding | Cantilever or Needle Scaffolding |

A) Supported Scaffolding

Support scaffolding, consists of platforms supported by standards anchored to the ground. Essentially, these platforms are built up from the ground level. Supported scaffolding provides sturdy support, and certain types allow for an unlimited number of layers. However, they can be challenging to use in situations where the ground is uneven or if there are space limitations at the base, such as on a roadway.

The major types of supported scaffolding are:

- Brick layer scaffolding or single frame scaffolding

- Mason's Scaffolding or Double Scaffolding

- Cantilever or Needle Scaffolding

- Trestle Scaffolding

- Mast Climber Scaffolding

- Ladder Jack Scaffolding

- Mobile Scaffolding

- Pole/Wood Pole Scaffolding

- Tube and Coupler Scaffolding

1. Brick Layer Scaffolding or Single Frame Scaffolding

Bricklayer scaffolding is the most common and cheapest scaffolding type as the scaffold is made out of single-row. Hence it is also called single scaffolding supported on the main wall using putlogs. The fact it is cheap is because it can be easily constructed and dismantled. It is mainly used in brick masonry construction.

|

| Fig.7. Brick Layer Scaffolding or Single Frame Scaffolding |

A single scaffolding consists of vertical members called standards fixed in the ground at 2.4 to 3 m intervals. These standards have a diameter of about 10 to 15 cm and are placed 1.2 m away from the building. Ledgers (horizontal members) join the standards at an upright gap of 1.2 to 1.5 m.

The putlogs (traverse members) are extracted from the gap that is remaining after the arrangement of standards and ledgers, to one end of the ledgers. It is placed at a gap of 1.2 to 1.5 m and usually has a length of around 90 cm.

When larger heights need to be achieved, additional cross bracings need to be provided for additional support.

Read More On:

Single Frame Scaffolding – Pros & Cons

2. Mason's Scaffolding or Double Scaffolding

Mason's scaffolding is used for stone masonry construction where more stronger scaffold is necessary compared to a brick layer's scaffold. In addition, like bricks, it is difficult to provide holes in the stone masonry walls to support the putlogs. Hence, a strong scaffold is made by providing double frames i.e. two rows of scaffolds put together to create an independent strong structure. Hence it is also called as double scaffolding or independent scaffolding.

|

| Fig.8. Mason's Scaffolding or Double Scaffolding |

Double scaffolding consists of the first frame made of standards and ledgers placed near to the wall, 20 to 30 cm from the wall as shown in Figure 7. The second frame is placed 1.3 to 1.7 m from the first series. Putlogs are supported over the ledgers (horizontal members) only. Over the putlogs lays the working platform.

Double scaffoldings may be supported additionally by diagonal braces in both the rows of the standards, and also by shores. This arrangement makes this type completely independent and ha more lateral rigidity.

3. Trestle Scaffolding

Trestle scaffolding is scaffolds used to work inside a room generally up to 5 m height from the supporting surface. Movable contrivances like a tripod, ladders, etc can be used to support the working platform and the scaffold. It is used for works like painting, repairs, etc.

4. Mast Climber Scaffolding

Mast climbers are vertically travelled motorized platforms attached to the outside of the building. A mast climber scaffolding is a type of vertical access system used in construction.

|

| Fig.11.Mast Climber Scaffolding |

It utilizes one or more vertical masts, which are sturdy support structures, to transport workers and materials up and down to various levels of a building or structure efficiently. This system helps speed up the completion of tasks and can be more cost-effective than traditional scaffolding methods.

5. Ladder Jack Scaffolding

|

| Fig.12. Ladder Jack Scaffolds |

A ladder jack scaffold is a basic type of scaffolding that uses two or more ladders leaned against a structure. Brackets are attached to the ladders, extending outward to support a platform or another ladder horizontally. It's important to note that ladder jack scaffolding is suitable only for light loads.

6. Mobile (Manual or Propelled) Scaffolding

Mobile scaffolds are supported scaffolds with wheels or casters, intended for easy movement. They're commonly used in tasks like painting and plastering, where workers need to move around frequently.

|

| Fig.12. Mobile (Manual or Propelled) Scaffolding |

7. Pole or Wood Pole Scaffolding

Pole scaffolding involves using wood for all structural parts. However, apart from bamboo scaffolding, which is mainly used in Asia, steel scaffolding has become the preferred choice due to its enhanced safety, reusability, and strength.

|

| Fig.13. Pole and Wood Scaffolding |

8. Tube and Coupler Scaffolding

A tube and coupler scaffold consists of platforms supported by tubes and assembled using coupling devices that connect uprights, braces, bearers, and runners (refer to Fig. 15).

|

| Fig.14. Tube and Coupler Scaffolding |

These scaffolds are often utilized in situations requiring the support of heavy loads or when multiple platforms are needed at various heights, such as spanning several stories. They offer flexibility in assembly directions, making them ideal for surfaces with irregular dimensions or contours.

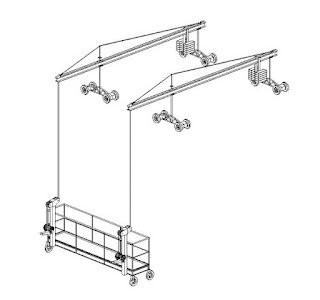

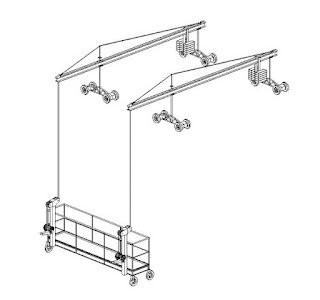

B) Suspended Scaffolding

Scaffolds with working platforms can be suspended from the roofs using wire ropes or chains. These types of scaffolding are called suspended scaffolding. It can be raised or lowered at any desired level. Suspended scaffoldings are mainly used for paintings, repair works, etc.

|

| Fig.15. Suspended Scaffolding |

The major types of suspended scaffolding are:

- Catenary Scaffolding

- Float Scaffolding

- Interior Hung Scaffolding

- Two-Point (Swing Stage) Scaffolding

- Multilevel Scaffolding

- Multipoint Adjustable Scaffolding

- Single-point Adjustable Scaffolding

- Cantilever or Needle Scaffolding

1. Catenary scaffolding

|

| Fig.16. Catenary Scaffold |

Catenary scaffolding involves the use of ropes or wires hanging from above a structure. These vertical ropes or wires connect to two others running horizontally and parallel to the structure, upon which a platform is placed. However, catenary scaffolding lacks mobility, making adjustments to height or relocation to new areas challenging.

2. Float Scaffolding

Float scaffolding utilizes fixed-length

ropes or wires hanging from a support beam parallel to the structure. These

ropes or wires support two ledgers, which in turn support the platform. Similar

to catenary scaffolding, float scaffolding is not mobile and is also known as

ship scaffolding.

|

| Fig.17. Float Scaffolding |

3. Interior Hung Scaffolding

Interior-hung scaffolding

resembles float scaffolding, but the ropes or wires hang from two parallel

support beams instead of one, both running parallel to the structure. (Figure 15)

4. Two-Point (Swing Stage) Scaffolding

Two-point (swing stage)

scaffolding is a common type of suspended scaffolding. It features a platform

supported at both ends by ropes or wires, allowing vertical movement. This type

of scaffolding is often seen hanging on the sides of skyscrapers.

|

| Fig.18. Two-Point (Swing Stage) Scaffolding |

5. Multilevel Scaffolding

Multilevel scaffolding is suspended

from the structure by ropes or wires, each supporting a ladder facing

perpendicular to the structure. Platforms run between the ladders, resting on

the rungs. Multiple layers can be created by extending the ladders if needed. (Figure 19(b))

6. Multipoint Adjustable Scaffolding

|

| Fig.19. Multistage, multilevel and single-point scaffolds |

In multipoint adjustable

scaffolding, a platform is suspended from overhead by four ropes, typically at

each corner. Unlike other suspended scaffolding types, this one can be raised

or lowered as needed, offering greater flexibility. It is commonly used in

structures like stacks, tanks, silos, and chimneys. ((Figure 19(a))

7. Single-point Adjustable Scaffolding

Single-point adjustable

scaffolding, also known as boatswain scaffolding, resembles multipoint

adjustable scaffolding but is suspended by a single rope or wire instead of

multiple. It's commonly used by solo window washers and features a suspended

chair for inspections, resembling the setup used by a boatswain on a ship.(Figure 19(d))

8. Cantilever or Needle Scaffolding

This type of scaffolding essentially consists of cantilever beams in the form of needle beams that pass through holes in the walls or windows. These cantilever beams support the temporary structure built over it. All the vertical members are supported on the series of needle beams taken out of the openings or the holes in the wall as shown in Figure 9.

|

| Fig.20. Cantilever or Needle Scaffolding |

Cantilever scaffolding is used when the:

- Ground is weak to support the standards (vertical members of the frame).

- To provide further stories in the existing building

- For repairing purposes

Scaffolding has been crucial for building tall structures throughout history. While wood scaffolding used to be common, steel is now more popular. New tools and alternatives like scissor lifts are also changing how some jobs are done. However, scaffolding remains essential and will keep evolving as we build taller and more complex structures.

0 Comments

Commenting Spam Links Are Against Policies