Search This Blog

Most Popular

Categories

- Building Construction (87)

- Building Materials (86)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (6)

- Concrete Mix Design (15)

- Concrete Repair (14)

- Concrete Slab (11)

- Construction Equipment (17)

- Construction News (7)

- Design of Structures (20)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (34)

- Material Testing (11)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (13)

- Structural Design (24)

- Structures (17)

- Transportation Engineering (9)

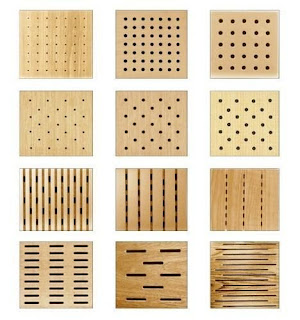

Perforated Acoustic Wooden Panels for Buildings

Perforated acoustic wooden panels are panels with perforations in various sizes and proportions to impart acoustic properties when used in the building interiors.

|

| Perforated Wooden Acoustic Panels Image Courtesy: Archello |

Perforated acoustic wooden panels are used for building walls or ceilings for different purposes like lighting, aesthetics, and most importantly acoustic sound control. Perforated wooden panels help to diffuse noise in different spaces and help to soundproof the space.

Perforated acoustic panels are an innovative solution to the problem of noise pollution. These panels are made with perforations on the surface of the panel, allowing sound to pass through while blocking out unwanted sounds. This allows people to enjoy music without disturbing others and also helps reduce the need for earplugs.

How Perforated Acoustic Panel Work?

The soundproofing properties of perforated acoustic panels are based on the perforations. Here, we need to understand the concept of Open Area Percentage.

Open Area Percentage represents the value of the amount of material that has been removed from the panel. For example, a perforated wooden panel with an Open Area Percentage of 20% implies, that 20 percent of the given panel has been removed via holes in the panel.

Now, what does the percentage of holes in acoustic panels mean? Higher the Open Area Percentage, the better the ability of the product to absorb noise. The perforations reduce the number of sound waves that are reflected off the surface walls and the ceilings, thus reducing echoes and noise.

|

| Perforations in Wooden Panel |

Features of Perforated Acoustic Panels

- The wooden acoustics panels can be made from timber, fiber cement, MDF, plywood, and plasterboard. The material is selected based on the environment.

- The size of the perforations in acoustic panels can vary from micro-perforations to larger perforations mainly based on the aesthetics, and lighting in addition to the acoustic features.

- Perforated wooden acoustic panels come in different finishing options including natural veneer, laminate, melamine, or RAL colors. Perforations can be provided in various shapes, curves and other custom features.

- The perforations of the wooden panels and the type of material impact the Noise Reduction Coefficient (NRC) value.

- The performance of the perforated acoustic panel is dependent on the air cavity and the insulation provided to the panel.

- Most high-quality perforated acoustic wooden panels provide durability from 10 to 15 years.

Also Read On: Modular Acoustic Screens for Construction Sites

0 Comments

Commenting Spam Links Are Against Policies