Search This Blog

Most Popular

Categories

- Building Construction (87)

- Building Materials (88)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (6)

- Concrete Mix Design (15)

- Concrete Repair (14)

- Concrete Slab (11)

- Construction Equipment (17)

- Construction News (7)

- Design of Structures (20)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (34)

- Material Testing (11)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (13)

- Structural Design (24)

- Structures (17)

- Transportation Engineering (9)

5 Ways to Insulate Your Metal Building

Team Prodyogi

November 24, 2022

Metal buildings are insulated where they need to withstand extreme temperatures and weather conditions. Insulation helps keep heat inside during cold months and cool air outside during hot ones.

|

| Image Credits: Brucha |

The performance of metal building insulation is dependent on the quality of the metal structure constructed. Hence, It is very essential to choose the best local metal building contractors in your location to develop high-quality metal buildings.

Whether you're looking to build a new metal building or renovate an existing one, you'll want to know about the various types of insulation available.

Vinyl-Faced Insulation for Metal Buildings

Vinyl-faced insulation is the most popular fiberglass insulation used for metal buildings. It is an insulation where the facing material of fiberglass blanket insulation is vinyl.

|

| Vinyl-Faced Insulation for Metal Buildings |

Vinyl as a facing material improves the capacity, protects the cover, acts as a vapor retardant, and behaves as an air and moisture barrier. Hence, it is an excellent insulation solution for metal buildings.

Vinyl-faced insulation is common for industrial and commercial buildings constructed from metal.

The cost of vinyl-faced insulation varies with the quality, thickness, and R-value it offers. The higher the R-value, the more effective will be the insulation

Spray Foam Insulation for Metal Buildings

Spray foam insulation is a liquid insulation material that can be sprayed on walls, roofs, attics, and other hard-to-reach spaces. These will help maintain the shape of the surface compared to different types of insulation.

Spray foam insulation can be closed-cell and open-cell insulation. Closed-cell spray foam insulation is commonly used for metal buildings as they are more water-resistant and durable. Open-cell insulation is used where the area needs to be highly soundproof.

|

| Open Cell Spray Foam for a Metal Building in Steelville, MO Image Credits: Foam Engineers |

Spray foam insulation is directly installed on the metal wall panels of the building. The surface must be prepared to accept the spray foam.

The cost of spray foam insulation is high and considered economical when performed as a do-it-yourself project.

Insulated Metal Panels (IMPs) for Metal Buildings

Insulated metal panels (IMPs) steel skins with an insulated foam core. They are now designed to be lightweight, and sleek with superior thermal properties and design flexibility. As they are lightweight, they allow fast installation for metal buildings.

|

| Insulated metal panels (IMPs) |

Insulated metal panels are suitable for both exterior walls and roof panels for metal buildings. They provide continuous insulation solutions.

Insulated metal panels are expensive and their installation requires special equipment and experienced supervision.

Foam Board Insulation for Metal Buildings

Foam board or rigid board insulation is a continuous insulation for metal building walls and roofs. These can be polyisco rigid foam boards or extruded or expanded polystyrene foam boards.This insulation is durable, follows most of the building codes, and reduces thermal bridging. The material is cited by the U.S. Environmental Protection Agency for a responsible impact on the environment.

|

| Foam Board Insulation for Metal Buildings |

Foam board insulation especially polyisco rigid foam board performs well in a temperature range of -100 F to 250 F. The material is economical compared to other insulation products and the R-value it offers. Its water absorption and vapor transmission are low.

Foam board insulation is expensive and they need to be trimmed in special dimensions based on the wall surface, keeping in mind the join conditions.

Filled Cavity System

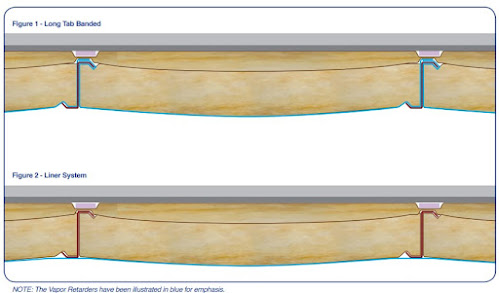

A filled cavity system is a type of insulation that fills the cavity between the purlins or roof panels or girts/wall panels with insulation. These can be of two types; Long Tab Banded and Liner.

|

| Image Credits: www.lamtec.com |

Both systems fill the cavity, the only difference is the orientation of the facing tabs.

- Long Tab Banded facing tabs are installed tight against the purlin and overlapped on top of the flange to maintain the continuity of the vapor retarder, see Figure 1.

- Liner facings are installed under the purlins, see Figure 2, above.

Advice on Buying Insulation

Insulation for metal buildings is a very important choice that if goes wrong would question the durability and comfortability of the building. The type of material that you choose for the building is dependent on the extent of insulation required, the comfort, the exposure area, and the future expected changes.

For large complicated buildings, it is advised to take assistance from an engineer who is well experienced in the same. If you are going to do it by yourself, insulation kits and packages are available with guidance on installation.

Most Visited

Soil Sampling Methods| Undisturbed and Disturbed Samples

November 08, 2023

Boring Methods for Soil Exploration

November 02, 2023

Steel Column Connected to Concrete Masonry Wall

October 11, 2017

How to Choose Good Quality Aggregates for Construction?

August 10, 2021

What are Infiltration Wells?

April 15, 2024

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Structure of Timber |Macrostructure and Microstructure

March 22, 2024

Search This Blog

MUST READ

What is PERT? Objectives, Pros & Cons

September 10, 2017

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Contact Form

Footer Menu Widget

Created By SoraTemplates | Distributed By Gooyaabi Templates

0 Comments

Commenting Spam Links Are Against Policies