Search This Blog

Most Popular

Categories

- Building Construction (87)

- Building Materials (88)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (6)

- Concrete Mix Design (15)

- Concrete Repair (14)

- Concrete Slab (11)

- Construction Equipment (17)

- Construction News (7)

- Design of Structures (20)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (34)

- Material Testing (11)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (13)

- Structural Design (24)

- Structures (17)

- Transportation Engineering (9)

Rebars in Construction | Types & Grades of Reinforcement Bars

|

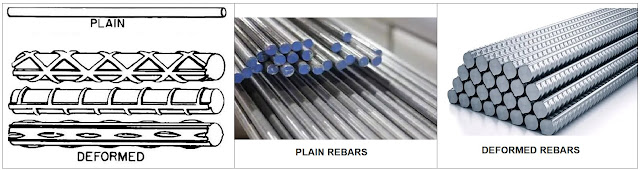

| Figure-1 |

Rebars used for concrete can be plain or deformed. Compared to plain rebars, deformed patterns on the reinforcement bars help the concrete adhere or bond to the reinforcing steel surface without slipping and together sustain tensile stress.

Plain and deformed rebars can be made of steel or fiber. The type of rebar is selected based on the material and properties suitable for the construction application.

Plain and Deformed Reinforcement Bars

1. Mild Steel Rebars

|

Types of nominal size of bars |

Ultimate Tensile Stress N/mm2 minimum |

Yield Stress N/mm2 |

Elongation Percent minimum |

|

Mild Steel Grade I or Grade 60 |

|||

|

For bars up to 20mm |

410 |

250 |

23 |

|

For bars above 20mm upto 50 mm |

410 |

240 |

23 |

|

Mild Steel Grade-II or Grade 40 |

|||

|

For barbars to 20mm |

370 |

225 |

23 |

|

For bars above 20mm up to 50 mm |

370 |

215 |

23 |

|

Medium Tensile Steel Grade-75 |

|||

|

for bars up to 16mm |

540 |

350 |

20 |

|

for bars above 16 mm up to 32

mm |

540 |

340 |

20 |

|

for bars above 32 mm up to 50 mm |

510 |

330 |

20 |

2. Carbon Steel Rebars

|

Grade |

GRADE

40 |

GRADE

60 |

GRADE

75 |

GRADE

80 |

|

Minimum

Yield Strength (psi) |

40,000 |

60,000 |

75,000 |

80,000 |

|

Minimum

Yield Strength (MPa) |

280 |

420 |

520 |

550 |

3. Low-Alloy Steel Rebars

|

Grade |

GRADE

60 |

GRADE

80 |

|

Minimum Yield Strength (psi) |

60,000 |

80,000 |

|

Minimum Yield Strength (MPa) |

420 |

550 |

4. HYSD Rebars

As per Clause 8.1 (Table 3) of IS: 1786-2008

|

Property |

Fe 415 |

Fe 415D |

Fe 500 |

Fe 500D |

Fe 550 |

Fe 550D |

Fe 600 |

|

Yield Stress |

415 |

415 |

500 |

500 |

550 |

550 |

600 |

|

Ultimate Tensile Stress |

10 percent more than the actual 0.2 percent proof stress/ yield stress

but not less than 485.0 N/mm2 |

12 percent more than the actual 0.2 percent proof stress/ yield stress

but not less than 500 N/mm2 |

8 percent more than the actual 0.2 percent proof stress/ yield stress

but not less than 545 N/mm2 |

10 percent more than the actual 0.2 percent proof stress/ yield stress

but not less than 565 N/mm2 |

6 percent more than the actual 0.2 percent proof stress/ yield stress

but not less than 585 N/mm2 |

8 percent more than the actual 0.2 percent proof stress/ yield stress

but not less than 600 N/mm2 |

6 percent more than the actual 0.2 percent proof stress/ yield stress

but not less than 660 N/mm2 |

|

Elongation (%) |

14.5 |

18 |

12 |

16 |

10 |

14.5 |

10 |

HYSD bars can be classified into cold twisted deformed bars (CTD bars), thermo mechanically twisted bars (TMT bars), and corrosion-resistant bars (CRS).

4.1. Cold Twisted Deformed (CTD) Bars

4.2. Thermo Mechanically Treated (TMT) Bars

4.3. Corrosion Resistant Bars (CRS)

5. Stainless Steel Rebars (SSR)

Stainless steel is the name given to a group of corrosion-resistant steel alloys that contain a minimum of 10.5% chromium. Stainless steel reinforcement is made of unalloyed steel which won't show any kind of corrosion and rust forming that is noticeable in normal environmental conditions. There are two main codes and standards today that incorporate the SSR. They are:- The British Standard BS6744

- The American Standard ASTM A955

Table-4: Tensile Requirements for Stainless Steel Rebars ATM A955

Property

GRADE 40

GRADE 60

GRADE 75

Tensile

Strength

psi[MPa]

70000 [500]

90,000[620]

100,00 [690]

Yield Strength

psi [MPa]

40,000[280]

60,000[420]

75,000[520]

The ASTM A955/A955M Standard Specification for Deformed and Plain Stainless-Steel Bars for Concrete Reinforcement. The bars are of three minimum yield strength levels namely Grade 40, Grade 60, and Grade 75, whose properties are given in Table-4. It is the main Standard for stainless steel rebar in the USA and Canada.

|

Property |

GRADE 40 |

GRADE 60 |

GRADE 75 |

|

Tensile

Strength psi[MPa] |

70000 [500] |

90,000[620] |

100,00 [690] |

|

Yield Strength psi [MPa] |

40,000[280] |

60,000[420] |

75,000[520] |

6. Epoxy-Coated Rebars

7. Galvanized Rebars

8. Low-Carbon Chromium Bars

|

Type |

A1035 CL |

A1035 CM |

A1035 CS |

|||

|

Grade |

Grade 100 [690] |

Grade 120 [830] |

Grade 100 [690] |

Grade 120 [830] |

Grade 100 [690] |

Grade 120 [830] |

|

Tensile Strength,

min, psi |

150,000 |

150,000 |

150,000 |

150,000 |

150,000 |

150,000 |

|

[MPa] |

[1030] |

[1030] |

[1030] |

[1030] |

[1030] |

[1030] |

|

Yield Strength

(0.2% offset), min, psi [MPa] |

100,000 [690] |

120,000 [830] |

100,000 [690] |

120,000 [830] |

100,000 [690] |

120,000 [830] |

|

Elongation in 8

in.[200 mm], min |

||||||

|

Bar Designation No.3 through 11 [10 through 36]14, 18, 20 [43, 57, 64] |

||||||

|

7 |

7 |

7 |

7 |

7 |

7 |

|

|

6 |

6 |

6 |

6 |

6 |

6 |

|

9. Rail and Axle Steel Bars

ASTM A996/A996M-16, is the Standard Specification for Rail-Steel and Axle-Steel Deformed Bars for Concrete Reinforcement. Three types of products are included, designated with a “rail symbol,” an “R” for bars made of rail steel, and an “A” for bars made of axle steel.|

Property |

Type

R Rail

Steel Bars |

Type

A Axle

Steel Bars |

||

|

Grade 50 |

Grade 60 |

Grade 40 |

Grade 60 |

|

|

Tensile

Strength, Min, psi [MPa] |

80,000 [550] |

90,000 [620] |

70,000[500] |

90,000 [620] |

|

Yield Strength, Min, psi [MPa] |

50,000 [350] |

60,000 [420] |

40,000[280] |

60,000 [420] |

The bars shall be rolled from standard section Tee rails or from carbon steel axles for railway cars and locomotives.

10. Fiber-Reinforcing Polymer (FRP) Rebars

|

Steel |

GFRP |

CFRP |

AFRP |

|

|

Nominal

yield stress, ksi (MPa) |

40 to

75 (276 to

517) |

NA |

NA |

NA |

|

Tensile

strength, ksi (MPa) |

70 to

100 (483 to

1600) |

70 to

230 (483 to

690) |

87 to

535 (600 to

3690) |

250 to

368 (1720

to 2540) |

|

Elastic

modulus, x 103 ksi (GPa) |

29.0 (200.0) |

5.1 to

7.4 (35.0

to 51.0) |

15.9 to

84.0 (120.0

to 580.0) |

6.0 to

18.2 (41.0

to 125.0) |

|

Yield

strain, percent |

0.14 to

0.25 |

NA |

NA |

NA |

|

Rupture

strain, percent |

6.0 to

12.0 |

1.2 to

3.1 |

0.5 to

1.7 |

1.9 to

4.4 |

0 Comments

Commenting Spam Links Are Against Policies